Dolce Gusto Filling Sealing Machine

Brief Instruction:

HSP serial Coffee Capsule Filling Sealing Machine use for Dolce gusto capsule is the latest Version Machine, High speed and high quality meet EURO machine standard, this model machine is design specially for nespresso capsule Filling and Sealing. Its material use is better than previous machines; Components use top brand.

* The whole machine stainless steel frame; Organic glass; two columns mould structure; Fixed castor and mobile pulley.

* Photoelectric detection the location of cup storage , If the cup storage is not enough, machine will alarm to feed capusles. and machine will automatic stop without capsules,

* The Sensor will detect the two lanes capsules, if one mould without capsules, this part mould will not filling coffee, and after sealing will be rejected automatic, other three lanes with capsules work in normal.

* Coffee servo screw filling, the filling volume can be adjusted on Touch screen, no cup no filling, lack of coffee in hopper, vacuum feeder automatically open.

* Nitrogen Sensor to detect whether there have Nireogen fill into capusles.

* Automatic vacuum suck lids, No cup no Lids suck. Lids suck fault automatic stop.*

* Sealing, Omron temperature controller to adjust the temperature.

*Automatic weight the finished capsules, if the weight is not meet the standards, the system will automatic reject this unqualified capsule into the waste box( which is) under the machine. and other qualified capsule suck up to conveyor to transport next working stations.

* Packing in Bag.

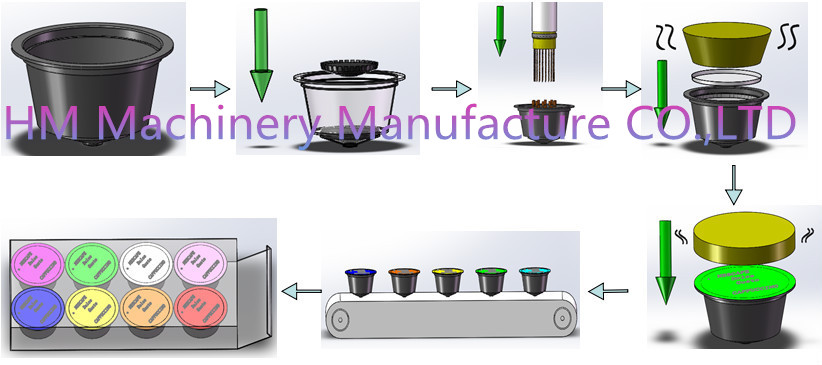

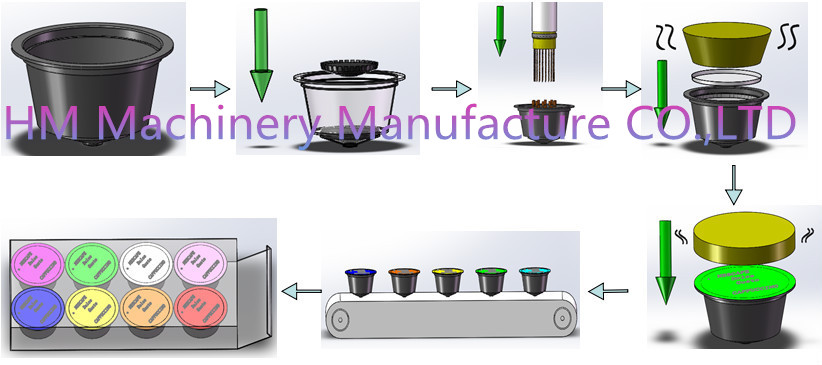

Main Working Process:

☆ Special Loading system for capsules

☆Automatic drop empty capsules to machine

☆ First time filling Nitrogen into capsule.

☆Automatic detect whether Nespresso capsule well loated on the machine by sensor.

☆ Servo motor to fill coffee while vibrating, weight around 5-20g ( can be adjust), also second time filling Nitrogen into capsule.

☆ The Third time filling Nitrogen into Capsule

☆Auto suck Foil Lids.

☆Auto detect whether the foil lids is ready by Sensor

☆ Auto Seal the aluminum lids.

☆ Automatic mechanical grasp the finished product to conveyor ( connect to the conveyor)

☆ transport the sealed capsule to the Bag Packing Machine,

☆ Bag packing

Technical Parameter:

We Also provide Emty good quality docle gusto, nespresso capsule etc.

More Photos:

HSP serial Coffee Capsule Filling Sealing Machine use for Dolce gusto capsule is the latest Version Machine, High speed and high quality meet EURO machine standard, this model machine is design specially for nespresso capsule Filling and Sealing. Its material use is better than previous machines; Components use top brand.

* The whole machine stainless steel frame; Organic glass; two columns mould structure; Fixed castor and mobile pulley.

* Photoelectric detection the location of cup storage , If the cup storage is not enough, machine will alarm to feed capusles. and machine will automatic stop without capsules,

* The Sensor will detect the two lanes capsules, if one mould without capsules, this part mould will not filling coffee, and after sealing will be rejected automatic, other three lanes with capsules work in normal.

* Coffee servo screw filling, the filling volume can be adjusted on Touch screen, no cup no filling, lack of coffee in hopper, vacuum feeder automatically open.

* Nitrogen Sensor to detect whether there have Nireogen fill into capusles.

* Automatic vacuum suck lids, No cup no Lids suck. Lids suck fault automatic stop.*

* Sealing, Omron temperature controller to adjust the temperature.

*Automatic weight the finished capsules, if the weight is not meet the standards, the system will automatic reject this unqualified capsule into the waste box( which is) under the machine. and other qualified capsule suck up to conveyor to transport next working stations.

* Packing in Bag.

Main Working Process:

☆ Special Loading system for capsules

☆Automatic drop empty capsules to machine

☆ First time filling Nitrogen into capsule.

☆Automatic detect whether Nespresso capsule well loated on the machine by sensor.

☆ Servo motor to fill coffee while vibrating, weight around 5-20g ( can be adjust), also second time filling Nitrogen into capsule.

☆ The Third time filling Nitrogen into Capsule

☆Auto suck Foil Lids.

☆Auto detect whether the foil lids is ready by Sensor

☆ Auto Seal the aluminum lids.

☆ Automatic mechanical grasp the finished product to conveyor ( connect to the conveyor)

☆ transport the sealed capsule to the Bag Packing Machine,

☆ Bag packing

Technical Parameter:

|

NO. |

Model |

HSP-6/ HSP-4 / HSP-2 /HSP-1 |

|

1 |

Speed |

Over 1800-12000 C/H |

|

2 |

Working station |

6/ 4 /2/ 1 lanes |

|

3 |

Filling range |

0-20grams |

|

4 |

Filling accuracy |

±1.5% |

|

5 |

Voltage |

280V60HZ/ 3KW |

|

6 |

Air pressure / gas consumption | ≥0.8Mpa?0.1m² |

|

7 |

WorkingTemperature |

5-35°C |

|

8 |

Relative humidity |

≤85? |

We Also provide Emty good quality docle gusto, nespresso capsule etc.

More Photos: